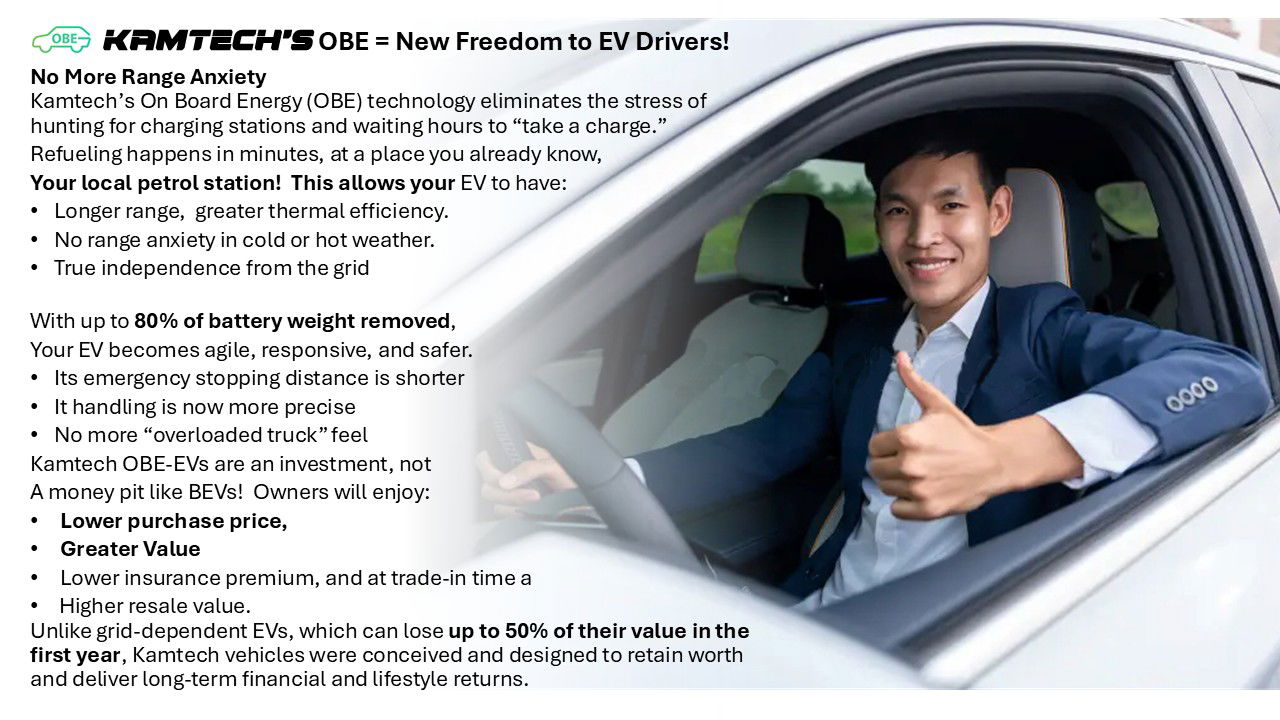

New Freedom For EV Owners!

Making Electric Vehicles + Positive

Expanding the Acceptance of EVs

Kamtech's On Board Energy is good for EVs owners!

On board energy is good for EV manufactures!

On board energy is good for the world!

According to new research from Harvard University, eight million deaths annually are linked to toxic pollution from fossil fuels burned to power the world’s electric grid. These emissions are packed with dangerous particulates and over 50 harmful chemicals. They don’t just cloud the skies. They damage the lungs, hearts, and futures of hundreds of millions.

Is it socially responsible to double or triple the health impact of this deadly energy source… just to charge the world's vehicles? What kind of world do you want your grandchildren to inherit?

🛠️Kamtech seeks to build a Cleaner, Greener World!

Electric vehicles powered by Kamtech’s On Board Energy system break the cycle. They no longer rely on coal- and petroleum-fueled power plants that spew toxic substances into the air and produce over 2/3 of the world's electric power. Kamtech's OBE has,

- No grid dependency

- No indirect emissions

- Virtually no harmful emissions.

🟢 Help us make the world a better place to live.

Kamtech first licensee is good for the air!

The next step in OBE long journey.

“I have not failed. I've just found 1,000 ways that won't work.” —Thomas Edison

Every transformative technology passes through three phases: concept, development, and commercialization. For the 4-stroke automotive engine, this journey spanned 37 years—from 1861 to 1898—until the Benz Motorwagen became the first mass-produced car.

The development of Kamtech’s On Board Energy (OBE) system followed a similarly demanding path. Fueled by dedication, not full-time effort, our mission was clear: to conserve energy and build a cleaner, more peaceful world.

Like the scholars whose innovations often remain buried in technical papers, our team faced countless setbacks. With perseverance, we often went to the authors themselves, who had hands-on experience in solving problems. The development was inspired and instigated by Professor Antoni K. Oppenheim, who outlined the original vision in a 1982 SAE paper. Early support was given by famous mechanic Smokey Yunic. Mark Beierle, of our first licensee, Earthstar Aircraft, helped perfect the platform, producing prototypes # 3-5. The production version in flight is seen above. Then, more recently, Professor Huynh Thanh Cong advised us on the final phase of the development. But history proves one truth: success is born from relentless iteration.

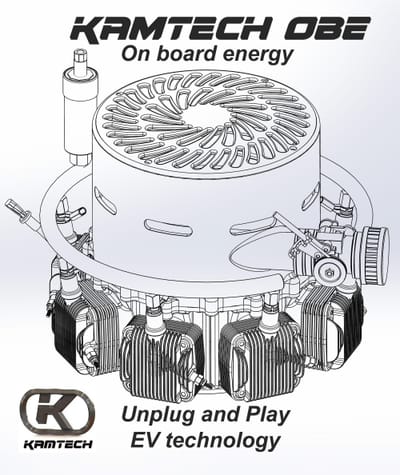

🚀 Ready for the Next Licensee

After years of redesigns, rebuilds, and rigorous testing, we’ve created a production-ready design of the Rad Cam engine, a compact, efficient power source that outperforms conventional 4-stroke engines in ease of manufacture, robustness, thermal efficiency, compactness, and cost. A modular design that has been:

- Proven in light aircraft

- Adapted for electric vehicles

- Refined through six prototype platforms and improved with hundreds of modifications.

🔗 Join us in powering the future, on the road and beyond.

Contact

- 21:04 Block E27 Belleza, Đ. Số 2, Phú Mỹ, Quận 7, Thành phố Hồ Chí Minh 700000

The Rad Cam Team players

Professor Antoni K Oppenheim

The person who ignited the Rad Cam RevolutionProfessor Antoni K. Oppenheim was more than a scientist—he was a visionary who reshaped the field of combustion engineering. His professional journey began in the 1940s, when he escaped war-torn Poland and contributed to advanced aircraft engine development in the UK. From the start, he tackled one of engineering’s greatest challenges: understanding the invisible interplay of flame fronts, pressure, and temperature inside the volatile chambers of internal combustion. While most accepted the limitations of the Otto cycle, Oppenheim saw its flaws clearly. He identified the hot flame front as the source of harmful NOx emissions, and the quenching layers as the cause of unburned hydrocarbons and CO. To him, solving these systemic issues—not masking them with catalytic converters or computer controls—was the true path to cleaner, more efficient combustion. Through groundbreaking research and influential publications, he offered solutions that challenged conventional thinking. Colleagues remember him as a quiet titan of innovation, always ready to provide multiple pathways forward when faced with complex problems. His insights became foundational to the design of the Earthstar Rad Cam engine, and ultimately shaped the development of Kamtech’s On Board Energy (OBE) unit. His legacy is profound. By liberating EVs from grid dependence and oversized batteries, Oppenheim’s influence continues to offer empowerment to manufacturers, drivers, and the future of transportation. Though deeply missed, his vision endures—illuminating the path toward independent, cleaner energy.

Smokey Yunick

Maveric of motion!Smokey Yunick’s career was legendary, spanning groundbreaking work with Hudson, Ford, and General Motors. More than an innovator, Smokey was a force of nature—known for bold ideas and relentless pursuit of performance. In 1991, when Duncalf set out to design the “ideal engine,” he turned to Smokey for guidance. While Professor Oppenheim had spent his life defining what needed to change in combustion and its environment, Smokey was uniquely qualified to show how to make it happen. Within days of hearing Oppenheim’s challenge, Smokey delivered a transformative insight for the shape of the cam: a constant acceleration profile. This radical design reduced initial force while increasing dwell time at both ends of the stroke, unlocking new levels of power, efficiency, and durability. It not only proved to greatly increase the efficiency of the spark ignition two-stroke version, but also promises to make managing the HCCI version much easier to accomplish. Smokey’s obsession with reclaiming waste heat and improving fuel economy directly shaped the Rad Cam engine. His recommendations—such as stainless steel pistons and heads with insulated coatings—became integral to its internal cooling system of the final design. More than his technical brilliance, it was his fierce, unwavering belief in the project that inspired the team. As one colleague recalled: “When Smokey believed in you, you had no choice but to rise to it.”

Mark Beierle

Engine designer/builderMark Beierle, owner of Earthstar Aircraft Company, was the first licensee of the Rad Cam engine. Leading his team through multiple prototype iterations, he played a crucial role in refining the design. The final prototype—a production-ready version—provided undeniable proof that Professor Oppenheim’s theories on combustion dynamics, documented in his papers and books, were correct. Together, Duncalf, Yunick, and Beierle transformed Oppenheim’s concepts into a functioning engine with a thermal efficiency approaching 50%—a groundbreaking achievement in powertrain innovation. Beierle’s expertise in engine design, his relentless dedication to building and testing, and his determination to see the Rad Cam succeed were instrumental in turning it into a practical and efficient power source capable of revolutionizing the EV sector. Had the economic crisis of 2008 not disrupted funding opportunities just as he was seeking seed capital, the project may have moved forward at an even faster pace. His efforts laid the groundwork for Kamtech's On Board Energy technology.

The Kamtech OBe Team players

Prof. Huynh Thanh Cong

HCCI and Injection Consultant🚗 Professor Huynh Thanh Cong is our Compression Ignition Expert. He teaches at the University of Science and Technology in District 10, Ho Chi Minh City, Professor Cong became an instrumental figure during a pivotal moment in the Rad Cam’s development. When the company that brought the project to Vietnam failed because of a lack of enginering skills, and manufacturing capability, it was Professor Cong’s insight and encouragement that revive the project’s momentum in Vietnam. Professor Cong is a recognized expert in fuel injection and compression combustion, with several published papers, as well as a noted consultant in the field. Professor Cong provided critical guidance on multiple engineering challenges—including the resolution of specialized material issues during prototype construction. “When others stepped back, he stepped in.” His technical acumen and steadfast support not only helped salvage the project but also solidified Vietnam’s role in the Rad Cam journey. His contributions remain embedded in Kamtech’s commitment to innovation and persistence.

Phạm Duy Tùng

Assembly Engineer🚗 Phạm Duy Tùng Despite being the youngest team member, Tùng has been with the project longer than any other team player. He has a background in advanced engine technologies, including hands-on experience with many of the industry’s most sophisticated engines. His contributions in the area of sourcing, adapting, and perfecting every component of the Rad Cam were invaluable to the project. Tùng is a vocal contributor in technical debates—his ideas, often grounded in obscure research or hard-won experience, steered the project clear of many problems. "Without Tùng’s tireless contribution, there would be no Kamtech OBE.”

D James Duncalf

CTO and Patent holder💡🚗Duncalf’s vision for energy independence is rooted in a family legacy of innovation. In 1923, at just 15 years old, his father built a wind-powered generator that electrified their farm—decades before rural electrification reached the region. Using salvaged railroad signal batteries, he stored enough energy from a wind-powered generator to power the family farm, earning local recognition as the area's first “electric farm.” However, just twelve years later, county authorities dismantled the system and forced connection to a centralized, coal-powered grid controlled by private interests. The experience revealed a lasting truth: we live in a world where individual ingenuity and people's freedom are often trampled on by politically connected corporate monopolies under the guise of societal benefits. ---------------------------------------------- Nearly a century later, the same dynamics persist. Across the globe, large electric energy providers seek exclusivity in automotive power markets, raising critical questions about sustainability, regulation, and public interest. Guided by the principle that cleaner, independent energy must remain possible! As we begin 2026, at least 20 major global automakers are currently planning or actively producing models with range-extender units, most of them using an engine system first patented over 160 years ago. Is it not time for EV companies to use twenty-first century technology to power their vehicles?

Kamtech's HCCI Technology Is Clean and Efficient

Actual Thermal Efficiency of a Pluged in EV!